More problems with Diesels

2 February 2022

Why do we have more problems with Diesel?

-p-500.jpeg)

We nicknamed 2015 “the year of the Diesel Bug”. That was when Marine Gas Oil finally came in line with Red Diesel ashore. It was when the sulphur content was reduced to 0.001% or 10 ppm. Sulphur acted as relatively good natural inhibitor and, without it, Diesel Bug has flourished, we here no end of stories of engines stopping because of sludge in the tanks.

But that is not the only consequence of removing the sulphur, over the next couple of months we will explain what has happened to Diesel, aka, Gas Oil, Red Diesel etc. We will explain why you have the problems and more importantly how to avoid them and what to do about them.

So what has happened?

Up to the 1990’s fuel generally came from low sulphur “Sweet” Crude Oil, it was the base stock to make standard gas oil we all got to use without a second thought.

“Sweet” crude is now a lot scarcer, so refiners use high toxic, high sulphur “Sour” crude. That in itself isn’t a problem, even as they now manage to squeeze double the amount of fuel from a barrel of oil than they did in 1990's, the gas oil was still fit for purpose without a second thought.

It then became evident the higher sulphur was harming the atmosphere and with reports of acid rain governments were compelled to do something about it. A program to incrementally reduce Sulphur levels was introduced resulting in Ultra Low Sulphur Gas Oil (ULSGO) with 0.001% sulphur.

So we had relatively low sulphur Sweet crude producing simple diesel. Now we have high Sulphur crude producing zero Sulphur.

This requires a much more vigorous refining techniques that result in removing the fuels natural lubricant and rendering it more prone to rapid oxidation and thermal degradation with poor stability that leaves deposits on fuel components and sludge in fuel tanks.

Why do we have problems now?

Removing the sulphur has also removed the “oiliness” or lubricating properties of the fuel that is essential to keep the fuel system components lubricated.

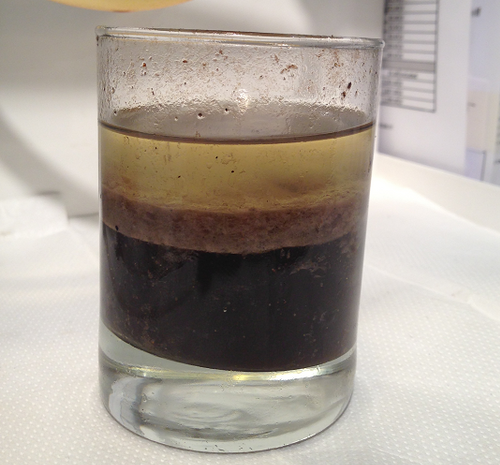

Because of the Bio content, fuel is a lot more hygroscopic and literally absorbs water from the atmosphere, this sinks to the bottom where it becomes the breeding ground for Diesel Bug.

Removing the sulphur has also removed the aromatic compounds that used to help keep asphaltenes in suspension. These asphaltenes now agglomerates the fuel rapidly degrades due to the heat and pressure experienced in it’s journey to the engine and back to the tank. The result is a tarry sticky sludge formation on the bottom of the tank that looks like Diesel Bug (slimy and stringy) but still blocks filters.

Removing the Sulphur and adding the Bio, which includes takeaway cooking oil, has also rendered the fuel unstable which leaves deposits in the injectors preventing them from functioning correctly so increasing fuel consumption, engine smoking and component failure.

The best advice we can give you is to have a fuel management routine. Whether you are a single vessel owner or manage a fleet, this should be key to your operation.

This is not a complicated process in fact, it can be broken down into 2 easy steps.

1. Remove the water, either via the drain or with a dewatering device.

2. Dose with the correct additive.

If you have any questions, you can contact the Marine 16 team, always happy to help

01686 622213 or email office@marine16.co.uk

Latest

PowerBoat & Rib

2 February 2022

Battle of the Diesel Bug Choose Your Weapons!

2 February 2022

ITS REAL- Fuel Contamination

2 February 2022

-p-500.jpeg)